New Arrival China Water Filter Replacement – OEM PP Cotton shower head cartridge filter Core – Xinpaez

New Arrival China Water Filter Replacement - OEM PP Cotton shower head cartridge filter Core - Xinpaez - Xinpaez water purification equipment Co., Ltd. Detail:

PP cotton Shower filter Core

Material quality: polyester fiber (PP material)

Replacement time: 3 to 6 months, depending on the water quality, normally 10000L.

Function: Filter the colloidal impurities, mud, rust, insect eggs, organic pollutants, etc

Filtration Rate: 5 Micron

Filtration Principle

The PP cotton filter element is made of polypropylene resin as a raw material to make fibers, which are bonded by the fiber itself. The structure of the filter element is a structure with thick outer layer fibers, thin inner layer fibers, loose outer layer, and tight inner layer. Filtering from outside to inside, the closer to the inner layer of the filter element, the smaller the pore size, the higher the filtration accuracy.

This unique gradient deep filtration has formed a three-dimensional filter residue effect, which can be multi-layered and deep structure, with large dirt holding capacity; PP melt blown filter element is strong, when the filter inlet and outlet pressure difference is 0.4Mpa, the filtration flow rate is large, and the pressure difference is small , The filter core is not deformed; It integrates surface, deep, coarse and fine filtration; It has the characteristics of large flow, corrosion resistance, high pressure. It is used to block large particles such as rust, sand and insect eggs in the water.

Replacement Instruction

Talking about the replacement, Because the PP cotton filter element belongs to the first-stage filter element when shower, more than 80% of the impurities will be filtered out at this stage, and the more impurities are filtered, the easier the filter element will be blocked. Therefore, the life of the PP cotton filter element is very short. The filter element may need to be replaced for more than two months in areas with poor water quality, and the longest area with better water quality will not exceed six months. So if you buy a shower head with a PP cotton filter element, in order to avoid secondary pollution, it is recommended that you replace the filter core every 3-6 months or so.

How to judge the quality of PP cotton filter element

1. Please check the weight. We can measure the weight with our hands. The heavier the weight, the higher the fiber density of the filter element. The quality is also better.

2. Please check the material. When choosing a filter, you must be optimistic about the material of the filter element. The color of the regular filter core is uniform and the surface is flat. The inferior filter surface is not uniform in color and poor in texture.

3. Compressibility. Generally, the higher the fiber density of the filter. The better the compression performance, the better the quality of the PP cotton filter core. We can judge by hand feeling, the stronger the hand feeling, the better the compression performance.

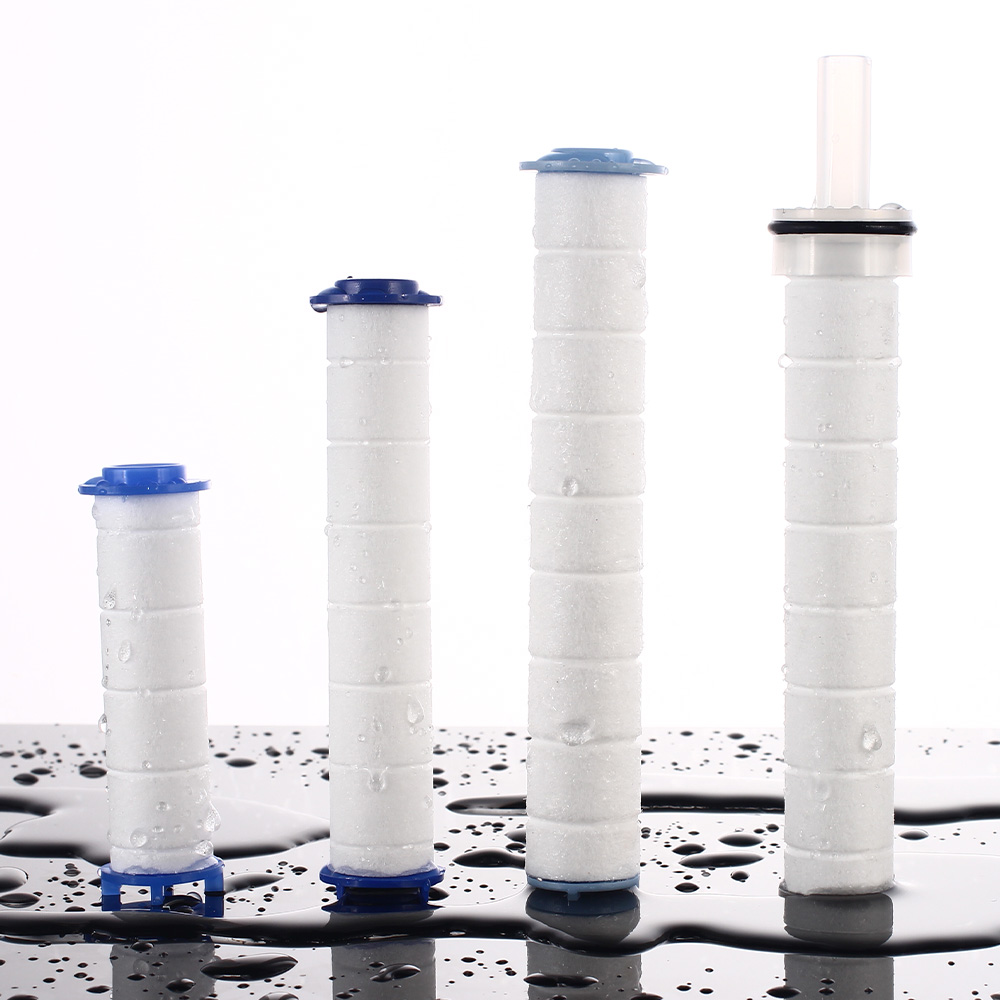

Generally we provide four sizes, OEM and ODM services available. No matter what size you need,

we can customize it. Currently we have 10 production lines working on PP Core with a monthly output of 2 million.

Product detail pictures:

Related Product Guide:

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for New Arrival China Water Filter Replacement - OEM PP Cotton shower head cartridge filter Core - Xinpaez - Xinpaez water purification equipment Co., Ltd. , The product will supply to all over the world, such as: Spain , Oman , Georgia , Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.